Sage 300 Newsletter – March 2016

Keeping You Up-To-Date With Information About Sage 300

Key Improvements Using a Warehouse Management System (WMS)

A warehouse management system (WMS) is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, put away and picking. The systems also direct and optimize stock put away based on real-time information about the status of bin utilization. A WMS monitors the progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations.[1]

Piasecki, Dave. “Glossary of Inventory Management and Warehouse Operation Terms”. InventoryOps.com. Retrieved 1 May 2015.

Warehouse management involves the receipt, storage and movement of goods, (normally, but not limited to finished goods), to intermediate storage locations or to a final customer.

Warehouse management systems often utilize automatic identification and data capture technology, such as barcode scanners, mobile computers, wireless LANs and potentially radio-frequency identification (RFID) to efficiently monitor the flow of products. Once data has been collected, there is either a batch synchronization with, or a real-time wireless transmission to a central database. The database can then provide useful reports about the status of goods in the warehouse.

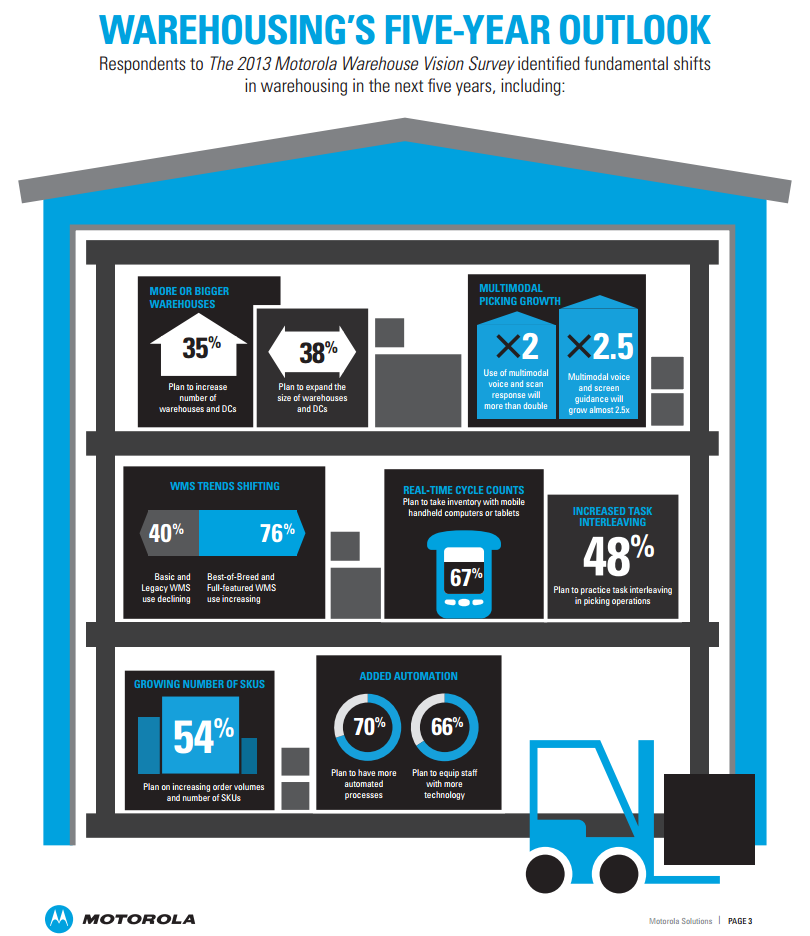

The need for increased inventory control, flexibility, speed, and more accurate fulfillment is high, especially as companies consider more and more of their warehouses and distribution centers as assets for competitive differentiation.

Key improvements utilizing a WMS system:

- Prevent shortages and production delays. Few things are worse than running out of parts and products right when you need them. To avoid costly delays in your manufacturing processes and customer order fulfillment, you should use inventory management software. It can help you know how much inventory you should keep on hand to meet demand.

- Track inventory levels in real time. This goes along with the first advantage. Knowing how much inventory you have at all times is helpful because it lets you make smart decisions about when to reorder products. Inventory management software instantly updates your records when you buy and sell products, which is much faster than entering that information by hand.

- Optimize warehouse organization. Speed is essential in having good customer service. Inventory management software makes your company move faster by improving your warehouse’s layout. You can group similar products together and position popular products in ways that make them easier to access when orders come in.

Recorded Webinar:

To see firsthand how a successful warehouse management system (WMS) implementation can provide a rapid Return On Investment, join supply chain visionary, Chris Barnes, as he delves into the business case and operational benefits for procuring and implementing a warehouse management system (WMS).

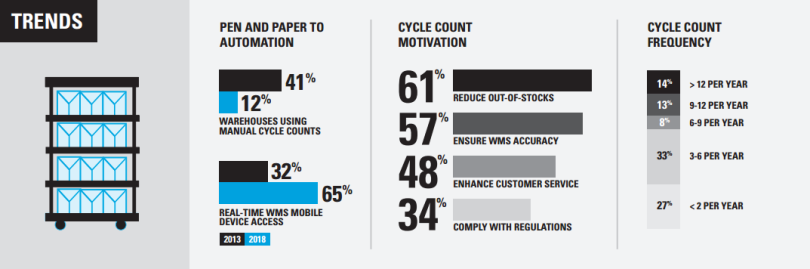

Automation of operational processes and equipping staff with technology seem to be the main areas to be improved.

For businesses that deal with tangible products, inventory management is a key element of that business’s success. Keeping tabs on where products are being stored, which vendors they come from, and how long they have been sitting on warehouse shelves are all key elements to successful asset management for businesses, no matter how small or large they might be.

Regardless of whether or not the products that one’s business sells are perishable, keeping a good sense of where they’re resting, how long they’ve been there, and how quickly they should be out the door is a crucial factor in maximizing productivity and keeping inventory upkeep, storage, and associated costs low.

Inventory management is also absolutely essential when it comes to avoiding issues such as items in the warehouse becoming obsolete. In the case of perishable products, it also helps schedule acquisition of goods and receipt of items in order to ensure that products are sold when they are at their peak freshness, and to ensure that overstocked inventory is avoided whenever possible.

Service providers and manufacturers also find that inventory management software is essential to manage the resources that they need in order to provide services or to create products. Whether a business sells a service or makes and retails a product, the good that is sold requires certain raw materials in order to be produced.

If your business has an inventory, you should be concerned with the performance, efficiency, and reliability of the inventory management software your business uses. If your business doesn’t use software to manage inventory – then you should be seriously concerned about losses in revenue and productivity that are probably affecting your business. Simply stated: almost every business needs some kind of inventory management software, no matter how big or small the firm might happen to be.