How to Move the Entire Content of a Stock from One Location to Another with Sage X3

How to Move the Entire Content of a Stock from One Location to Another with Sage X3

One of the many configuration demands when it comes to physical inventory stock control within ERP system such as Sage X3 arises when we are faced with the reorganization of our warehouse locations. The reorganization can require the renaming of actual physical stock locations not only in the warehouse but within Sage X3.

This challenge can become laborious within Sage X3 when we have preexisting inventory already within a bin that is now in the process of being renamed. The process can be especially demanding when we store more than one raw material or finished goods within a single location. The question we face is how can we do this as straightforward and as quickly as possible within Sage X3?

Fortunately, there are processes we can use through the front-end software to assist, please note that these transactions can also be done on the handheld or through the or the Windows Telnet Client from a command prompt.

Using ADC Stock Change by Identifier [VXBSC]:

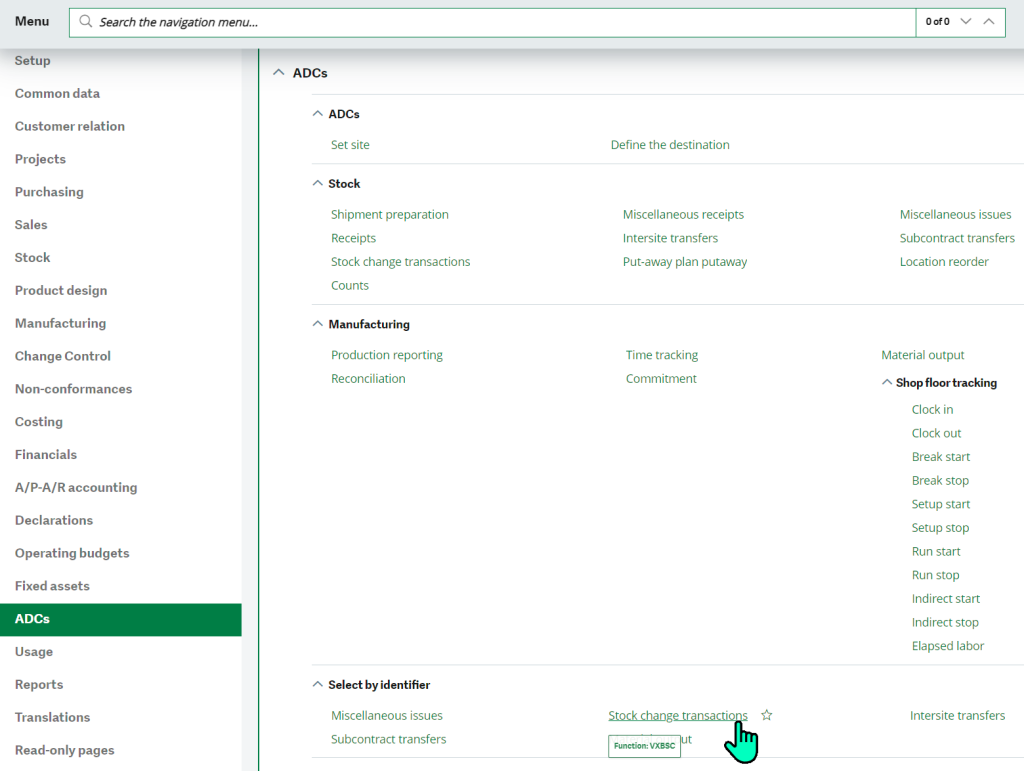

The screenshot below is the location in X3 navigation menu to perform the stock change via the ADC Web Client functionality.

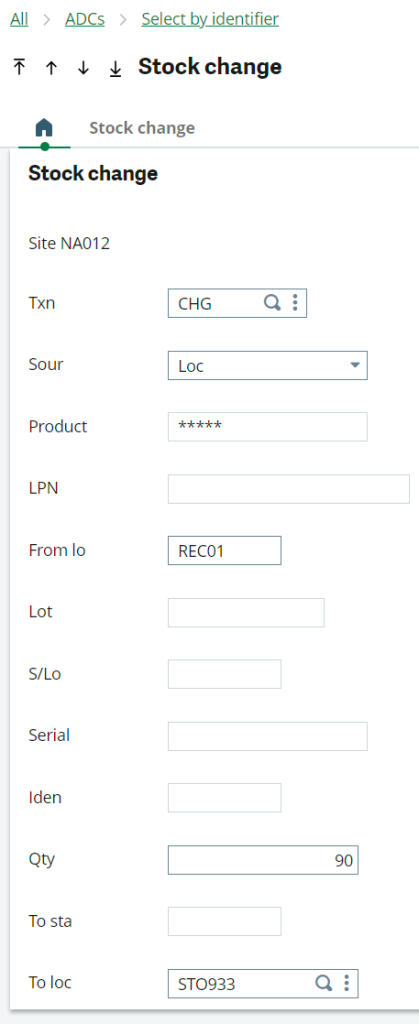

Once the user selects the “Stock change transaction” function the screen below will appear. Please note that this is a “one for all” transaction function where every product in the current location will be moved to the new location. In our example everything from “REC01” is being moved to the new location “STO933.”

Using stock change transaction [GESSCS]:

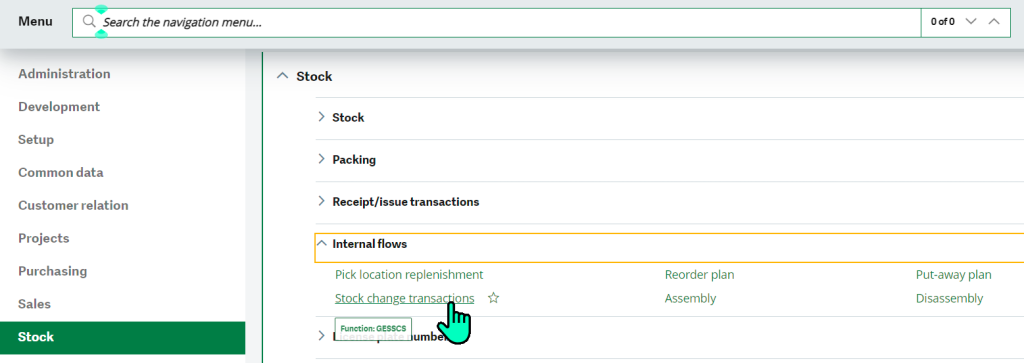

Using X3 software function from the Navigation menu – the user can select location, destination location, and then select all the contents to be moved, which can allow the user to leave some of the items in the existing bin if required.

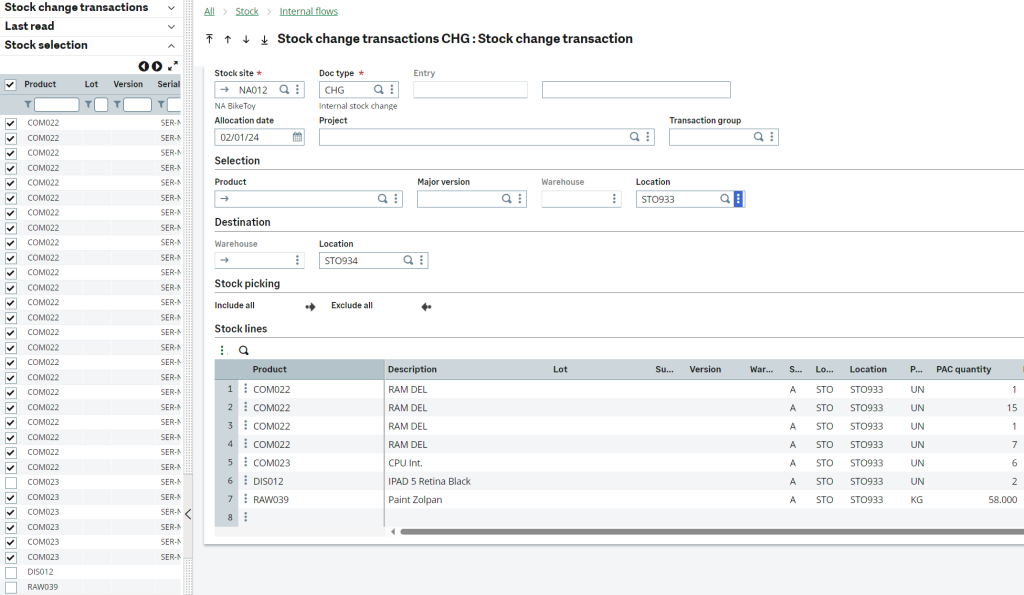

This screenshot is a view of the products and their “Left List” selection during the Stock Change process. In this example the selected products are moving from location “STO933” to location “STO934.”

These functions, although not very common, can save time when it comes to physical and system stock location changes during year-end inventory counts or cycle count processes, when changing bin locations, location IDs, or warehouse changes are very common. Other examples can be during a reorganization, opening a new warehouse, adding new racks and bins, and rotating and moving stock during this process is highly likely.

As stated previously this type of functionality is very useful for companies who combine different products often in bin or rack locations and find a business requirement to constantly rotate products to a new location. The function allows the user to move the entire content of location from Bin “A” to “B” for example. This function also will work with serial and lot tracked inventory items, as well as not tracked items.

One final note is that this ability to move products all together cannot be used on products assigned to an LPN number within Sage X3.

If you find this to be something that would be helpful to your organization below are where you can find them through the Sage X3 Web Client Navigation page.