Changing Material Quantity Consumed for Subcontract POs in Sage X3

Changing Material Quantity Consumed for Subcontract POs in Sage X3

As part of the subcontract setup in Sage X3, there is a parameter in the Receiving Entry transaction in the “SUBCONTRACTING STOCK” block that defines the Material consumption mode. There are 3 options:

- Consume all the planned material with the first receipt, regardless the quantity received.

- Consume the material proportionately to finished product received without exceeding the planned quantity.

- Consume material proportionately based on the finished product.

That said, this setting can be overridden at the time of receipt. The processed outlined below, illustrates how this is done. It allows you the flexibility to control how much of the raw material is consumed on a receipt by receipt basis.

Step-by-step instructions:

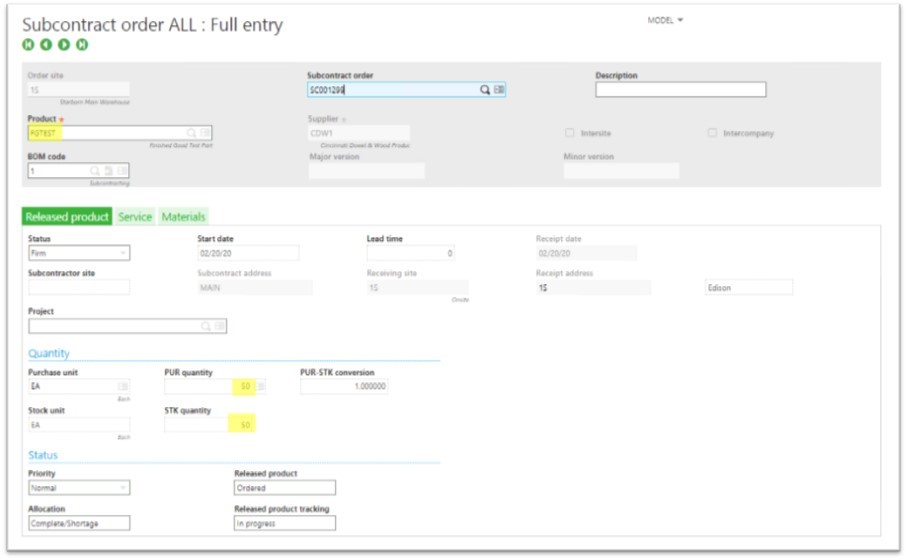

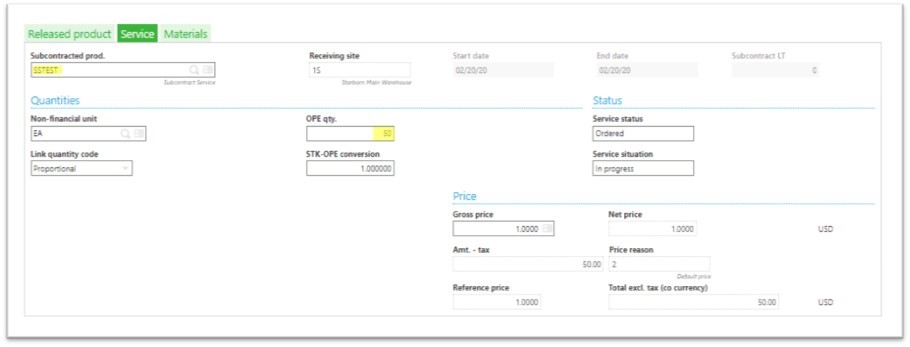

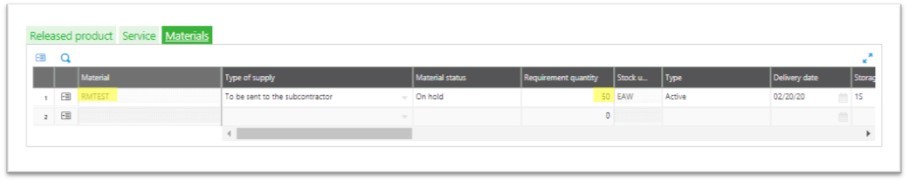

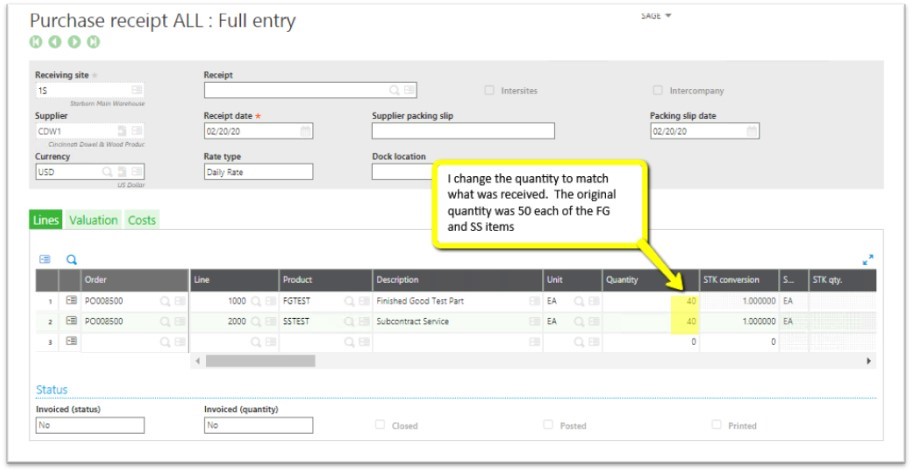

1. Create a subcontract order as normal and generate the subcontract PO. In the example below we ordered 50 each of FGTEST. This translates to 50 each of RMTEST and SSTEST, raw material and subcontract service, respectively.

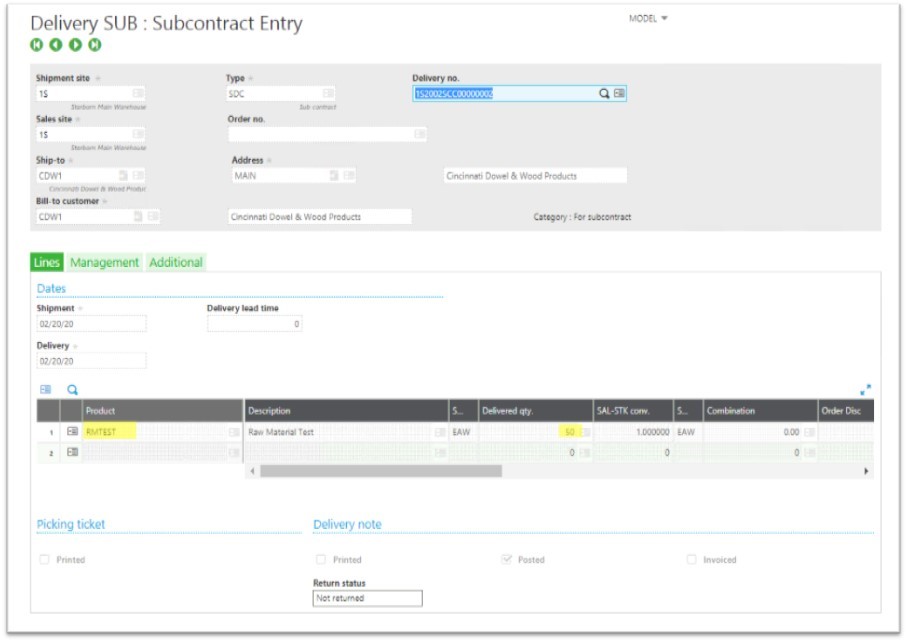

2. Create the delivery and validate to ship 50 each of RMTEST to the supplier.

3. Receive the finished good (FGTEST) from the supplier. The assumption here is that the supplier only produced 40 of the required 50 of FGTEST but consumed all the material.

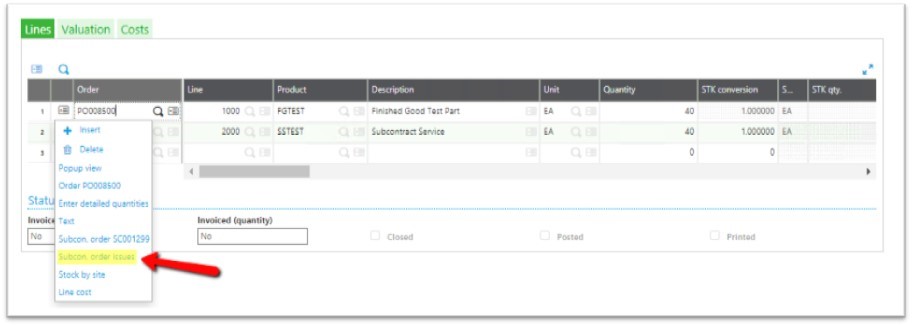

4. Before clicking “Create”, click on the Action menu at the beginning of the line for the FG item and select “Subcon order issues”.

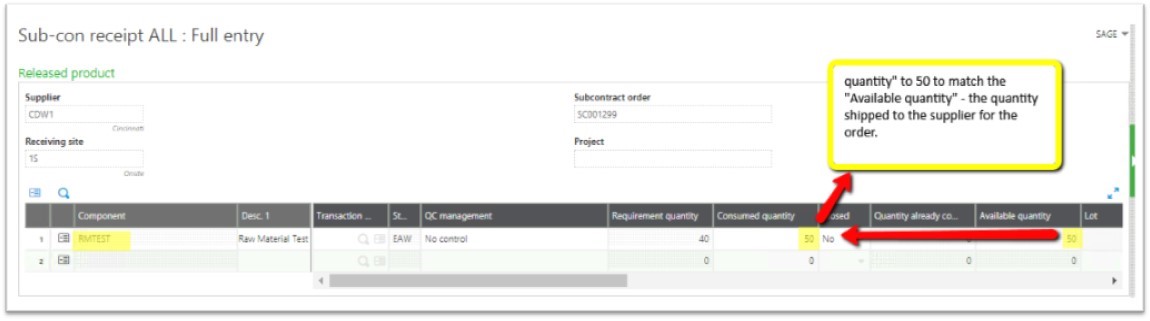

5. The following window will appear. Change the quantity to 50 to match the “Available quantity” and consume all the RM shipped to the supplier. After you change the quantity, click “OK”.

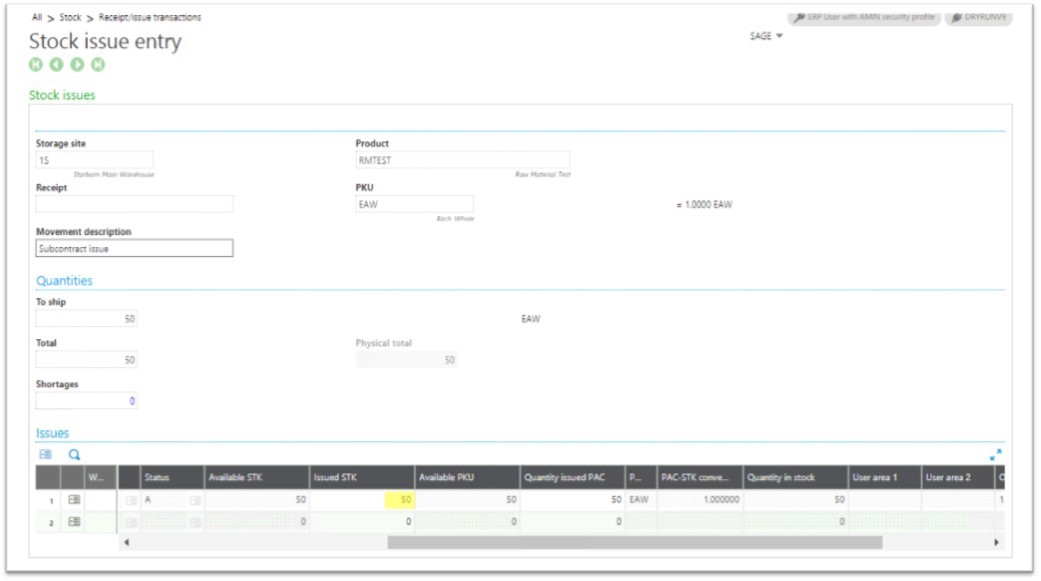

6. The Stock Issues screen will appear. You must change the quantity here too and click “Save”.

7. Click “Create” and finish the receipt.

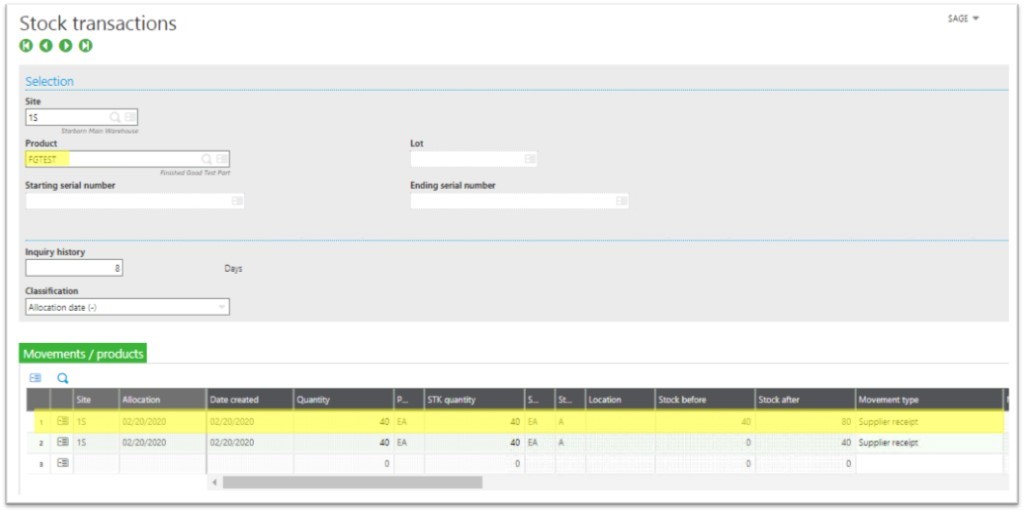

8. Stock Transactions show 40 each of FGTEST being received to stock.

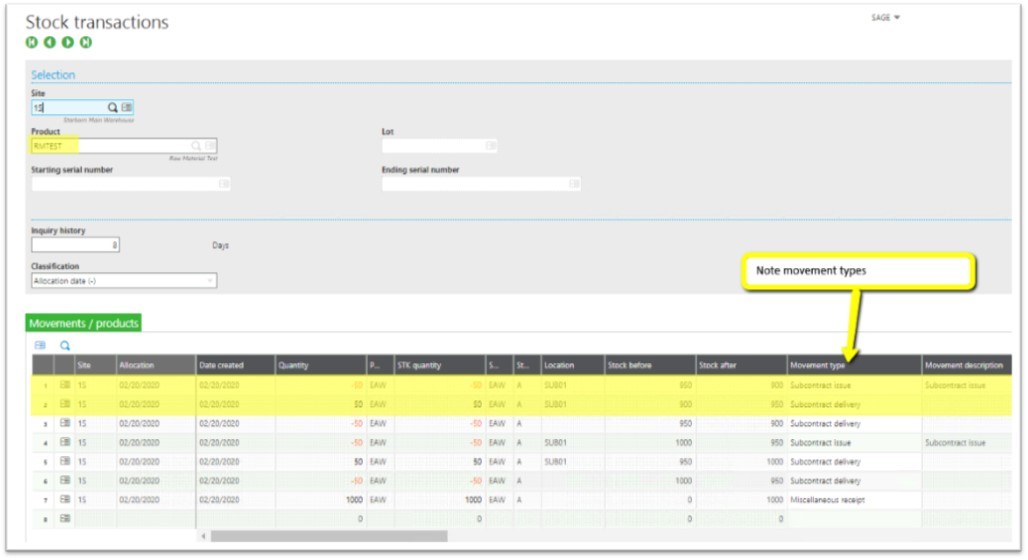

9. Stock Transactions will also show all 50 of RMTEST being consumed from the subcontract location.